Concrete Flooring Contractor Markham

Obtain professional concrete flooring in Markham that's designed for durability and code adherence. Our service includes carefully formulated compositions, tested consistency/aeration/thermal and humidity/acidity/relative humidity analysis for reliable hardening and attachment. We handle abrasive blasting/mechanical grinding to ICRI CSP, crack/joint repair, and quick-drying base coats. Select polished concrete, epoxy/polyaspartic systems, or pigmented/enhanced appearances with ultraviolet-resistant coatings and certified floor measurements and coating depth. We validate credentials, warranties, and timelines to minimize hazards, expenditure, and operational impacts-next, see how sector-specific options fit your facility.

Essential Points

- Expert concrete flooring services in Markham: featuring precise mix formulation, structural reinforcement, joint placement, and curing processes following industry codes for predictable strength and lasting quality.

- Certified contractors with WSIB and liability coverage, delivering thorough written project outlines, QC testing, guarantees meeting ASTM/CSA requirements, and dependable completion schedules.

- Surface preparation and moisture management: relative humidity and pH evaluation, CSP profiling, crack and joint restoration, vapor barriers, and compatible primers for installations that meet warranty requirements.

- For polished, stained, or dyed concrete finishes, we deliver comprehensive solutions including advanced grinding methods, lithium densification, UV-stable protective coatings, slip resistance applications, and sample demonstrations to ensure aesthetic satisfaction.

- We implement epoxy/polyaspartic solutions with controlled mil thickness, moisture-blocking primers, non-slip aggregates, and certified FF/FL specifications for producing durable, low-maintenance floor solutions.

The Importance of Expert Concrete Flooring in Markham

While concrete may appear simple, proper installation in Markham is crucial for weight-bearing capacity, surface evenness, water control, and long-term expenses. You require a qualified contractor who precisely calibrates mix design to match slab thickness, reinforcement specifications, and ground conditions, then validates slump characteristics, air content levels, and temperature conditions for consistent curing. Industry experts plan for regional climate conditions-including freeze-thaw cycles, de-icing materials, and moisture levels-by specifying controlled air content, optimal water-cement ratios, and correct joint spacing.

Additionally, you avoid compliance risks. Skilled crews understand building codes, oversee vapor barriers, reinforcements, and curing compounds, and document compaction and compressive strength tests. Expert finishing delivers FF/FL targets, reducing trip hazards and racking issues. Proper drainage gradients and isolation joints stop heaving and cracking. To summarize, professional methods protect structural reliability, reduce callbacks, and increase service life.

Polished Concrete: Sophisticated Design Meets Long-Term Reliability

Upgrade functionality and appearance with polished concrete that creates durable, clean, gleaming floors crafted for durability and performance. You get a durable surface refined through advanced grinding, honing, and click here densification processes to maximize durability and minimize porosity. We then seal and burnish to secure clarity and chemical tightness.

Fine-tune the finish you need-from satin to micro mirror finish-while keeping slip resistance through aggregate exposure choices and controlled light reflectivity control. This optimizes brightness efficiency, lowers maintenance, and streamlines cleaning processes. Surface flaws and seams are addressed before finishing to avoid early deterioration and surface marking.

Anticipate reliable lifecycle costs, quick return-to-service, and easy compliance with hygiene and dust requirements. A polished concrete surface ensures stable performance without finishing layers, delamination, or delamination risk.

Durable Epoxy Finishes for Garages, Workshops, and High-Traffic Zones

You'll need epoxy coatings that can resist abrasion, hot-tire pickup, oils, salts, and common solvents without degrading or discoloring. To ensure this type of performance, you should mandate mechanical surface preparation (using grinding or shot blasting), moisture and pH testing, and a compatible primer to secure maximum bond strength. Then you should apply the epoxy following manufacturer MVT guidelines, regulate application thickness and cure duration, and finish with a UV-stable topcoat when traffic or UV exposure demands it.

Durability and Chemical Resistance

When operations require a floor that won't fail under stress, epoxy coatings provide high compressive strength, durability against wear, and established chemical protection for manufacturing areas, repair shops, and heavily-used passages. You gain longevity from strong molecular bonds within the bonded structure, resulting in shock absorption, form retention, and lasting durability. Epoxy resists vehicle traffic, heavy equipment, and wheeled loads without scratching or breaking down.

Furthermore, you minimize degradation from oils, fuels, coolants, road salts, and various solvents. The protective film blocks penetration, reducing surface damage and separation when accidents happen. Temperature fluctuations and water vapor are managed with limited expansion, protecting bond integrity. Select solids content and resin-hardener ratios to suit environmental demands. With the appropriate treatment, you lower maintenance costs, extend service intervals, and keep operations online.

Surface Preparation and Application

Before epoxy performs effectively, thorough surface preparation establishes performance limits. You must verify slab moisture, pH, and tensile pull-off, then remove weak surface material and impurities. Execute concrete surface profiling using mechanical preparation methods to attain the specified CSP, creating a clean, porous surface. Address cracks and joints with semi-rigid fillers, and detail edges where failures start.

Begin by sealing porosity using quick-drying primers that tolerate residual moisture and reduce recoat times. Spread material to full coverage in areas non-slip properties or depth must be achieved, then spread the body coat using a roller or squeegee at the target thickness, ensuring wet edge consistency and full coverage. Regulate ambient and substrate temperatures, dew point, and airflow. Complete with a UV-resistant topcoat to protect against surface damage, chemicals, and allow for straightforward maintenance in parking areas and heavily trafficked areas.

Custom Concrete Staining and Dyeing for Unique Colors and Patterns

It's possible to create a specific color palette using acid stains for variegated tones or water‑based dyes for crisp, uniform hues matched to brand or design standards. We'll create pattern and texture effects-stenciling, sawcuts, multiple layers, and deliberate color variations-to create stone, tile, or graphic looks with uniform results. To lock in color and performance, we'll select the right sealer (polyurethane, polyaspartic, or penetrating), then create a maintenance plan with neutral pH cleaners and scheduled sealer applications based on traffic.

Color Palette Options

Color plays a vital role in designing concrete surfaces, and stained and dyed applications yield accurate, reproducible effects. You pick from calibrated color sets that match brand standards or project palettes, then we verify with physical samples under your actual lighting. Acid stains create variegated Earthy tones-terra cotta, brown, gray-suited for commercial, public, and retail environments needing low-glare warmth. Acetone dyes and water-based dyes expand into rich gemstone colors-emerald, sapphire, ruby-enhancing navigation and high-end display areas.

We evaluate surface conditions like porosity, moisture content, and cement makeup to determine absorption, then establish mixing ratios, contact duration, and application methods for uniformity. UV-resistant sealants secure pigmentation, while gloss levels tune reflectance targets. You achieve consistent coloring across processes with recorded mixing specifications and quality checks, delivering reliable, sustainable outcomes.

Pattern and Texture Effects

After establishing hues established, patterns and textures function as performance elements that guide flow, minimize glare, and define zones. You can utilize stained or dyed concrete as the color base, then add controlled designs to achieve measurable results. Scored grids, machine-cut boundaries, and precision-etched motifs establish wayfinding solutions and merchandise areas without extra hardware. Impressed finishes deliver non-slip micro-topography while mimicking natural materials or branded designs. Acid stains create natural effects; water-based dyes achieve uniform, repeatable colors for precise motifs.

We strategically plot circulation paths, dock approaches, and retail vignettes so textures guide movement and rest areas. Matte finishes reduce glare from LED systems, preventing camera flare and optimizing optical comfort. Border treatments and insertions match identity requirements, supporting durability, safety, and efficient installation.

Essential Care and Sealing Advice

Achieve optimal sustained performance by aligning the sealer to the finishing system, exposure requirements, and traffic classification. Choose penetrating sealers for permeable, UV-protected stained surfaces; select high-solids polyurethanes or polyaspartics when wear and harsh substances are common. Check VOC limits and slip prevention values. Ready thoroughly: verify neutral pH following staining, complete 200-400 grit burnishing if specified, and install within the manufacturer's designated recoat window.

Implement seasonal evaluations to assess gloss retention, surface protection, and scratch patterns. Measure wear areas at high-traffic zones and heavy-use areas; plan selective recoat before surface degradation. Establish a regular spill response protocol: contain, absorb, treat, and clean - no acidic cleaners or undiluted degreasers. Utilize microfiber dust control, power wash with pH-neutral detergent, and implement sacrificial finish in heavy-use sections. Monitor maintenance metrics to optimize lifecycle expenses.

Essential Guidelines for Surface Preparation and Moisture Control

Before any coating or overlay can be applied, thorough surface preparation and moisture control determine warranty eligibility and performance. Initial steps include various tests: ASTM F2170 RH probe analysis, ASTM F1869 calcium chloride testing, and pH measurements. Then, remove contaminants, followed by substrate profiling to the required ICRI CSP, utilizing diamond grinding or shot blasting. Repair all cracks, spalls, and joints with compatible materials, and vacuum thoroughly to achieve a dust-free surface prior to priming.

Handle moisture concerns from the start. Confirm existing under-slab vapor barriers are performing correctly; where barriers are absent or compromised, implement moisture management solutions suitable for your slab's moisture levels. Manage structural cracks and seams with elastic compounds to accommodate shifts. Specify primers based on epoxy or urethane suited to moisture requirements. Record moisture readings, prep techniques, and cure periods to ensure compliance with manufacturer warranties and achieve reliable outcomes.

Business, Industrial, and Home Applications

Validated prep and moisture control establish the basis for performance across segments, but application priorities vary by use case. In commercial settings, you need to balance traffic patterns, design elements, and lifecycle costs. You choose sustainable aggregates for environmental certification, hardening agents for abrasion resistance, and coatings optimized for slip resistance without compromising maintenance efficiency. You must account for thermal expansion at entrance areas and glass-enclosed courtyards.

In manufacturing settings, you need to focus on impact resistance, chemical tolerance, and forklift traffic patterns. You methodically develop joint patterns for storage areas, determine optimal reinforcement needs, and implement coatings that manage thermal expansion from process heat. Noise reduction is essential in proximity to testing labs and QC departments.

In residential settings, the focus is on convenience and minimal upkeep. We incorporate sound-reducing underlayments, radiant-prepared base layers, and specialized sealants that provide slip resistance while maintaining a warm and inviting appearance.

Picking the Perfect Contractor: Experience, Coverage, and Timeframes

When choosing a concrete flooring contractor in Markham, evaluate credentials and delivery discipline with similar diligence you use for mix designs. Confirm the company maintains licensed installers, has WSIB and liability insurance, and has manufacturer certifications for the chosen system (polished, epoxy, urethane-cement, or overlays). Validate project references with similar loads, exposure, and schedule constraints.

Require a comprehensive scope outlining: substrate prep, moisture control, reinforcing elements, application, surface completion, and quality control testing. Request a warranty that outlines coverage, restrictions, and response times; link it to industry standard measurements such as load capacity, flatness/levelness (FF/FL), and coating mil thickness.

Evaluate timeline viability by checking: workforce planning, machinery access, cure time windows, and backup arrangements for adverse weather and supply disruptions. Create a well-defined conflict resolution process, escalation contact list, and daily status reporting protocol.

Financial, Maintenance, and Value Assessment

Once you have these key project parameters, align the budget with long-term operational efficiency, instead of focusing on upfront costs. Assess installation expenses alongside lifecycle pricing to include concrete specifications, structural support, joint design, curing methods, and coating systems. Specify surface treatments based on abrasion resistance, chemical exposure requirements, and slip resistance factors to avoid premature failures.

Define maintenance plans ahead of the pour. Schedule chemical maintenance, reseal intervals, and crack mitigation techniques to safeguard finish quality and levelness specifications. Factor in estimates for grinding and polishing touch-ups, joint filler replacement, and humidity management as required.

Consider total cost of ownership: energy reflectance (reduced lighting expenses), service intervals for maintenance, and projected lifespan. Document warranty conditions associated with usage and environmental conditions. Quantify market value by demonstrating regulation-compliant surfaces, low pending maintenance, and portable warranty coverage. You'll reduce unexpected expenses and maintain property worth.

Frequently Asked Questions

Do You Accommodate Off-Hours Installation to Minimize Disruption to Business?

Yes. We offer after-hours and weekend installation scheduling to limit downtime. Our team manages overnight arrangements and send emergency personnel when necessary, while phasing work to preserve access and safety. Our team manages curing procedures, noise reduction, and dust management to satisfy operational constraints. We offer comprehensive schedules, site-specific staging, and swift team placement. You'll receive status reports, quality verification, and comprehensive project completion records, making sure your facility resumes operations as scheduled with clean, compliant, and lasting outcomes.

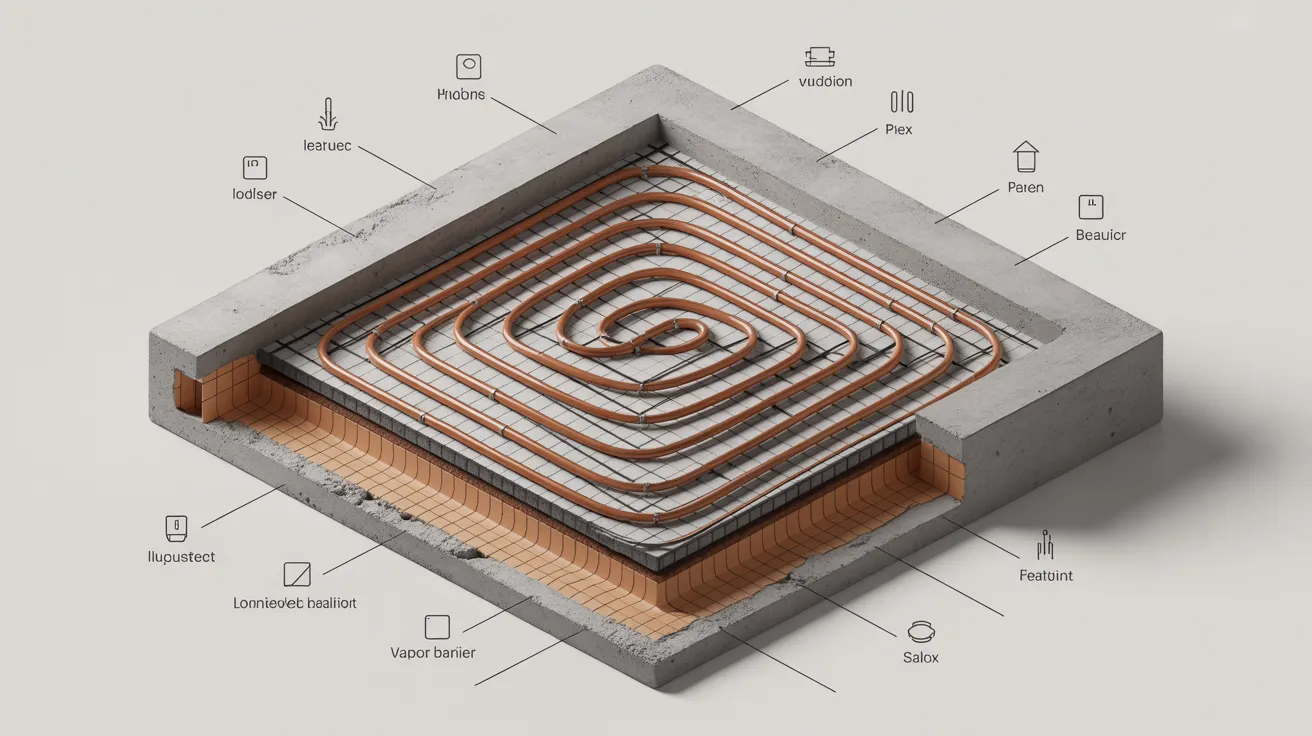

Can You Install Underfloor Heating In Concrete Floor Applications?

Yes, you are able to integrate radiant floor heating with concrete flooring systems. Consider it like crafting a masterpiece: attention to detail is essential. You select hydronic systems for extensive zones and power savings, or electric mats for targeted zones and rapid response. You coordinate slab thickness, insulation, vapor barriers, and control joints to safeguard tubing/cables. You validate load calculations, spacing, and system configurations, then initiate pressure and continuity tests, ensuring uniform heat, minimal thermal lag, and durable performance.

Tell Me About Your Environmentally-Friendly and Low-VOC Product Selection?

You can select environmentally friendly systems using low-volatile sealers, waterborne epoxies, and solid-content urethanes to minimize environmental impact and installation time. Select mixes with reclaimed materials, SCMs (fly ash, metallurgical slag), and local sand to reduce embodied carbon. Choose lithium-silicate densifiers with ultra-low VOC profiles. Request polished concrete to avoid topical coatings where possible. You'll obtain resilient, wear-resistant surfaces, compliant with LEED/WELL requirements, without compromising cure times, adhesion, or lifecycle performance.

Do You Handle Permitting or Liaise With Condominium Boards in Markham?

We deliver permit assistance and condo coordination in Markham. You won't have to deal with red tape; we manage applications, submit drawings, and monitor approvals. We coordinate with property managers, security, and boards to harmonize bylaws, noise windows, elevator bookings, and load limits. We furnish insurance certificates, WSIB, site-specific safety plans, and engineer letters as required. You receive clear timelines, stakeholder updates, and documented compliance, making sure your project stays on schedule and inspection-ready.

How Well Can You Match Current Concrete Finishes in Partial Renovation Projects?

Yes, matching existing concrete finishes while undertaking partial renovations. Begin by conducting a detailed assessment, performing material composition testing, granular composition study, and sheen benchmarking. Implement color matching via stains, dyes, or pigments calibrated with test panels. Execute texture replication by implementing specialized troweling techniques, shot-blast profiles, or micro-topping stamps. Regulate cure rates and gloss using densifiers and guard coatings. Verify with test comparisons under project lighting to ensure seamless integration.

Final Thoughts

You're looking for a floor that performs like a well‑tuned engine-built to spec, clean, and long-lasting. With polished concrete, epoxy, and stains, you'll coordinate design with functionality, foot traffic, and lifespan. Careful surface prep and moisture mitigation eliminate expensive repairs. Verify experience, warranty coverage, and project planning to maximize returns while minimizing risk. When you select proven Markham specialists, you'll lock in a finish that stands up to heavy use, harsh substances, and operational delays while reducing upkeep needs and lifetime expenses for years.